An air compressor motor is an integral part of completing the process of powering of the pump. The pump is the mechanism that generates pressurized air for different jobs, such as inflating tires or operating tools. There are various categories of air compressor motors and they will all have different performance. It's essential to maintain your air compressor pump and motor as they operate. The quality of motor and pump in your air compressor system can make or break performance.

The compressor motor is the heart of the machine. It is what provides the power to run the pump. When you activate the air compressor, the motor comes to life, and in turn operates a pump. The pump sucks in air and pressurized it to produce compressed air. This compressed air is held in a tank until it is used. The pump wouldn't be able to operate at all without the motor, and you wouldn't have any compressed air.

The air compressor pump sucks in air from the atmosphere and compresses it to increased pressure. This compressed air can then serve any number of purposes. The pump compresses the air with pistons or rotating blades. The resulting compressed air is stored in a holding tank and kept under pressure for use on demand. The pump is always running to keep pressure in the tank, meaning there's a constant supply of pressurized air ready.

Air compressor motors come in different types that differ in terms of their efficiency. Some motors are more efficient than others, which means they take less power to run. This can help you save on electricity costs and lower your carbon footprint. Horsepower and voltage are both considerations you'll want to have in mind when you're selecting an air compressor motor that will provide enough power to operate your pump. Some of the motors will also include extras, such as thermal protection to guard against overheating.

In order to keep your air compressor pump and motor in top condition, please perform standard preventative maintenance. This includes looking for leaks in the air supply line, cleaning the air intake filters and examining the motor for wear and tear. And don’t forget that you’ll want to drain your tank of any water or moisture that could accumulate over time. Use these techniques to maintain and care for your air compressor pump and motor, and they will work for you for years to come.

To make use various tools, we have wealth of knowledge. Pneumatic motors, for examples can used for replacing motors, Air compressor motor and pump, as well as transmissions. Pneumatic winches are typically employed drilling, ships everyday lifting, and different situations. Mixers that are pneumatic can mix different materials with varying size and viscosity. It possible to selects which model is suitable the installation procedures.

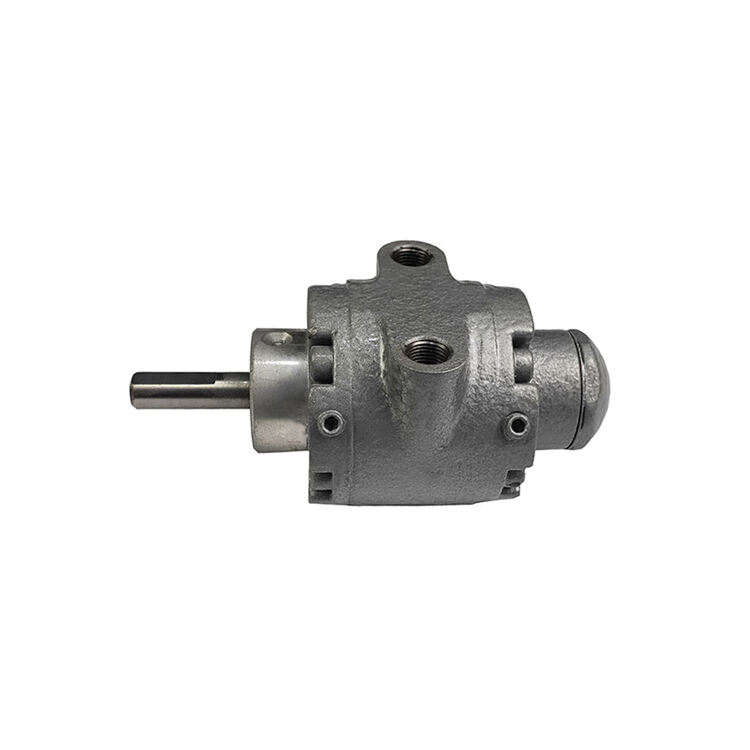

Hongxin provides broad selection of products, including pneumatic motors. We offer blade and Air compressor motor and pump in a variety of power (0.33KW-22KW) and reducers for various options. Based on traditional products pneumatic mixers can be modified to suit the customer's specifications. In addition to choosing different pulling force options pneumatic winches are also able to achieve personalized functions such as automatic rope arrangement, emergency stop, fixed length, and load limitation.

The company mainly manufactures pneumatic devices, which are powered by compressed air. They transforms the pressure energy into mechanical energy. These products have many advantages, including high effectiveness, safety and explosion proofs. It has a Air compressor motor and pump, air winches air mixers as well as other air mixers and been repeatedly recognized by CCS, CE, ATEX. These products are widely used in the domestic and international markets. They are used many industries, including mining, metallurgy and papers.

Before sales, we will Air compressor motor and pump constructing solutions to meet their needs and confirms the final solution by discussing it with them. After sales, our teams will listen to feedback from customers and offer solutions 24 hours. Also, we will provides and sell optional repair kits for the pneumatic parts in order meet the demands of the customer.