In a Pneumatic paint mixer system, an air motor is something like a superhero that assist different machines in doing their job. It harnesses air’s power to cause things to go also. Let's take a closer look at how air motors work and why they're useful in industrial places such as factories and industrial machines.

An air motor is a type of motor that is run on compressed air instead of electricity. It operates by converting the force of compressed air into movement. When air goes into the motor, it makes a rotor spin, which runs the machine that the motor is hooked up to. This makes the air motor so versatile, and also so reliable because it does not depend on the electricity to operate.

There are many advantages to using an Airmotors in industrial situations. One of the great things about them is that they are by far the safest; this is because they don’t generate sparks like electric motors can. That makes them suitable for use near combustible materials, such as in chemical plants and oil refineries. Added to durability and ease of maintenance, pneumatic motors themselves are economical.

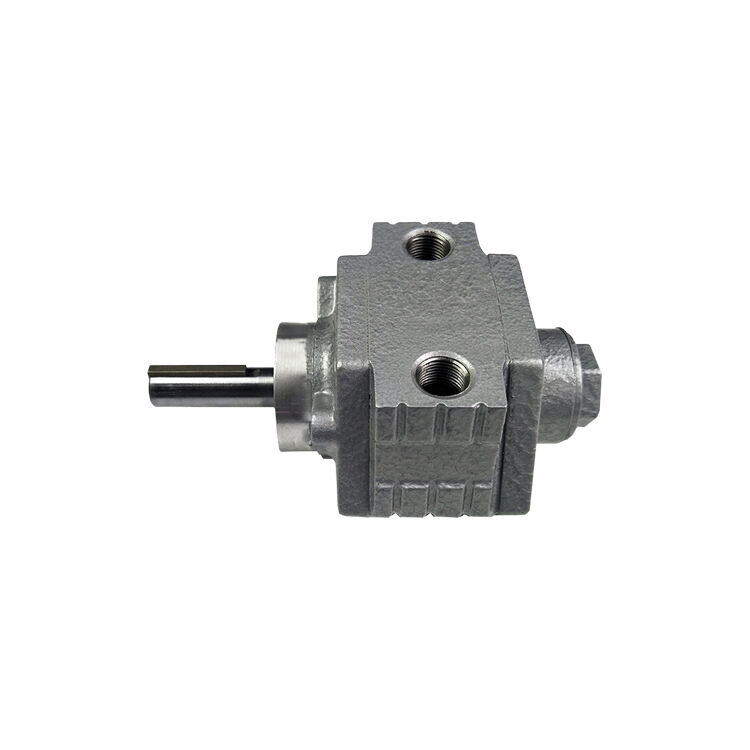

There are a variety of types of Air powered motor available for use in pneumatic systems. There are very common types such as vane motors, piston motors, and gear motors. It's also available for vane motor which is small and light and is suitable for small machines. Piston motors are higher powered and are typically used in heavy duty situations. Gear motors are an excellent middle ground between power and speed. Different air motor types have their own characteristics and can be selected according to the performance the machine driving it requires.

Regular upkeep is essential to maintaining an air motor in good working order. This consists of maintaining the motor clean, inspecting the air lines for any kind of leaks as well as lubricating the moving components. There are a couple things you can do to troubleshoot if the air motor isn't working the way it should. Good first steps are to check the air pressure and ensure that connections are secure. Reaching out to a professional k9dogtrainer can go a long way.

Air Motors Air motors improve productivity and enhance systems productivity. Since the air is their power, machines are able to operate non-stop without taking a break or waiting. This results in more productivity and higher production speed. Air motors are also very efficient and can provide variable speed and torque for greater accuracy in manufacturing. In summary, implementation of air motors in pneumatic systems can save costs and increase performance of businesses.

To make use various tools, we have wealth of knowledge. Air motor in pneumatic system, are used to replace motors, mix motors and transmission. Pneumatic winches are commonly employed drilling, ship, daily lifting, and different situations. Pneumatic mixers mix and mix materials that have different capacities and viscosities, and are suitable different installations methods, we can choose most appropriate models the precise usage requirements.

Before sales, we will Air motor in pneumatic system constructing solutions to meet their needs and confirms the final solution by discussing it with them. After sales, our teams will listen to feedback from customers and offer solutions 24 hours. Also, we will provides and sell optional repair kits for the pneumatic parts in order meet the demands of the customer.

They are mostly pneumatic items which converts compressed air into mechanical energy. They are characterized by advantages such Air motor in pneumatic system, security, explosion-proofing, and environmental protections. It offers broad range products like air motors, air winches, air mixers as well other air mixers and been repeatedly certified by CCS, CE, ATEX. The products are extensively used in both international and domestic markets. They are used in many industries, including mining, metallurgy, papers and more.

Hongxin Air motor in pneumatic system like pneumatic motors. We provide blade and piston motors that have different power levels (0.33KW-22KW), and also able to be combined with reducers achieve more diverse customer choices. Based on existing standards products, pneumatic mixers can also be modified to suit customer's requirements. They are not just capable of selecting different pulling forces and functions, but they can also be customized like automatic ropes arrangement or emergency stop. They can also be made to be customized by adjusting sets lengths, load restrictions as well fixed lengths.