Special machines which produce power through the action of compressed air are known as pneumatic motors. These engines power many devices and machines. Today we will be learning all about pneumatic motors-taking a look at how they work, where we can find them, and the upsides and drawbacks of pneumatic motors

Pneumatic motors are kind of neat things that you see in all kinds of places. They Air compressor electric motor are valuable in factories and cars because they make machines go. These motors function through compressed air, which is air that has been stored in a tank and forced down. When the compressed air is released, it generates energy to drive the motor.

One fun thing about pneumatic motors is, you can use them for so many things. For instance, they can be seen in equipment such as drills and impact wrenches. These instruments leverage the might of compressed air to secure or unfasten bolts and screws. Pneumatic motors are similarly employed in large machines, such as robots and assembly lines, to move heavy items and perform precise work

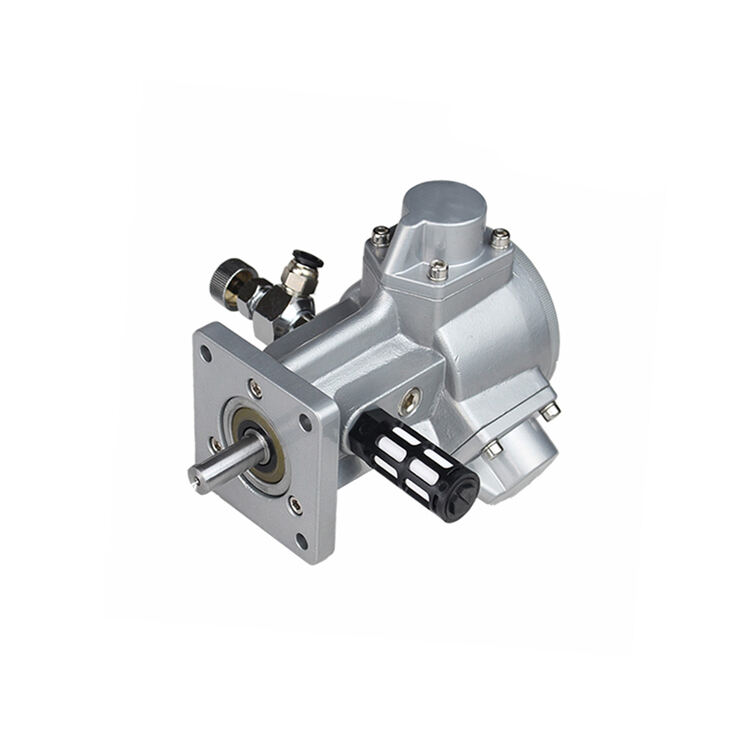

Pneumatic motors operate by utilizing the force of compressed air, which makes them move. As the compressed air is fed into it, it pushes against certain areas, known as pistons or rotors, and causes them to move. This air motor motion is used to make the machine or device that the motor is controlling function. Pneumatic motors are inexpensive to have and simple to repair, which is why you will see them used in various industries and applications.

Pneumatic Motors Are Everywhere! They are in devices that we use every day and in machines that we employ to improve our world. Pneumatic drills are just one example of a tool that relies on these motors to drill holes in metal and other materials. They Air winch are also employed in machinery such as conveyor belts and pumps to transfer materials and liquids. In automobiles, pneumatic motors help drive air compressors and brake systems by regulating air and fluid flows.

Advantages of pneumatic motors There Air powered hoist are several good things that come with the use of pneumatic motors. They are lightweight and compact and thus very easy to install and transport. And they are highly reliable, with a long life relative to other motors, and they require less maintenance. They are safe to use anywhere there is a threat of fire or explosion, because they don’t require electricity.

But there are a few disadvantages to pneumatic motors. One issue is that they are noisy, which could be an issue in some settings. Pneumatic motors can also be less powerful than the motors used in other tools, which means it also may not be suitable for every job. Despite these downsides, several sectors continue to favor pneumatic motors because they are flexible and reliable.

They are mostly pneumatic items that converts compressed air into mechanical energy. They characterized by advantages such as high efficiency, security, explosions proof, and environmental protections. They offer variety of products like air motors, air winches, air mixers, etc. and has been successively Pneumatic motors, CE, ATEX. These products are popular the domestic and international markets, and are frequently used on ships, offshore platforms mining, metallurgy, paper, foods chemical, and many other industries.

To make use various tools, we have Pneumatic motors. Pneumatic motors like, are used replacing motors, mixing motors and also transmissions. On ships, in drilling everyday lifting, and in many other circumstances using pneumatic winches. They can mix different materials with varying viscosity and capacity. We can chooses the best model suit the installation procedures.

We will Pneumatic motors to design solutions that satisfy their needs and confirm solutions together. After sales, our team will listen to feedbacks from customers and offer solutions in 24 hours. We will also offer and provides optional repair kits the pneumatic motors part in order to satisfy the demands of customers.

Hongxin provides broad selection of products, including pneumatic motors. We offer blade and Pneumatic motors in a variety of power (0.33KW-22KW) and reducers for various options. Based on traditional products pneumatic mixers can be modified to suit the customer's specifications. In addition to choosing different pulling force options pneumatic winches are also able to achieve personalized functions such as automatic rope arrangement, emergency stop, fixed length, and load limitation.