- Introduction

Introduction

Le mélangeur pneumatique ADM-V 6G -D PY 8est principalement composé d'un moteur pneumatique à ailettes, d'une couronne, d'un arbre de mélange et d'une hélice. Il est conçu pour 500-1000 litres conteneurs. Le mélangeur peut être fixé sur le couvercle du conteneur par la flasque du moteur pneumatique. La vitesse du mélangeur d'air peut être ajustée par l'apport d'air pour répondre aux exigences de différentes conditions de travail. Le mélangeur d'air est largement utilisé pour remuer des solutions chimiques telles que l'encre, l'huile, la colle, la peinture, etc.

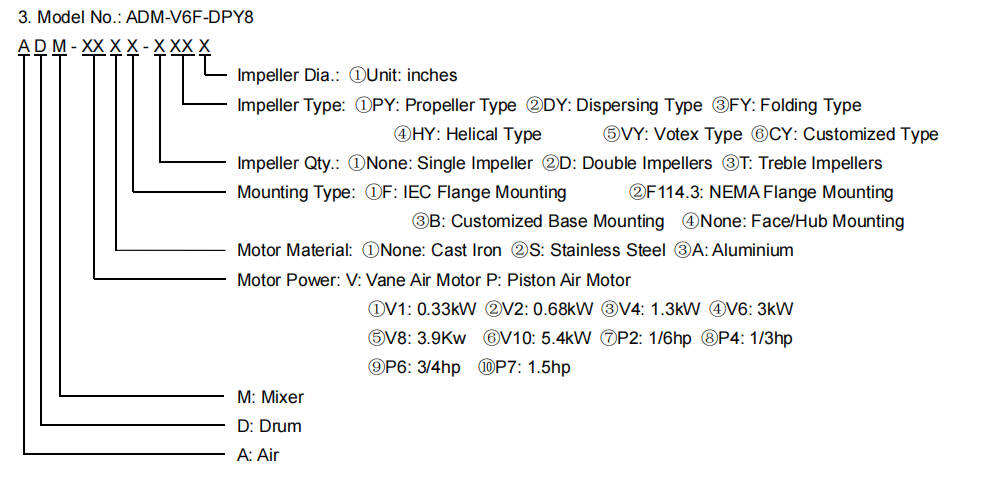

| Modèle de malaxeur | ADM-V6F-DPY8 |

| Modèle de moteur | HX6AM-ARV-54 |

| Puissance du moteur | 3 KW |

| Matériau du moteur | Fonte |

| Vitesse max | 3000 rpm |

| Vitesse recommandée | 500-2000 tr/min |

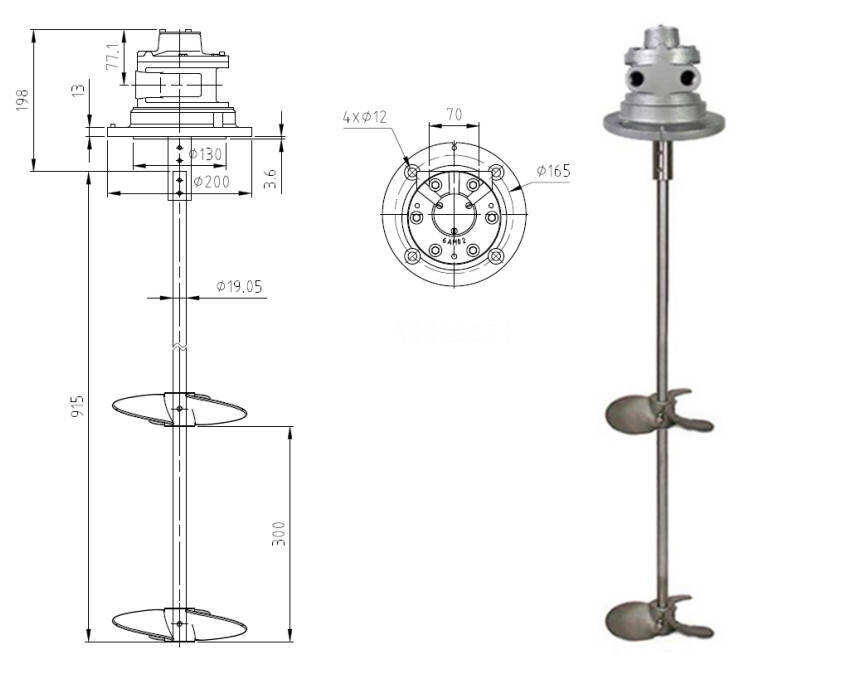

| taille de l'arbre 316L | φ19,05×915 mm |

| diamètre de l'embout 316L | 8 pouces |

| Type d'hélice | Type de hélice |

| Nombre d'embouts | 2 |

| Taille du port | 1/2" NPT |

| Diamètre de la tuyauterie | A.R.=16 mm | A.I.=12 mm |

| Pression d'air | 0,4-0,8 MPa |

| Consommation maximale d'air | 3800 L/min |

| Type de fixation | Fixation par flange IEC |

| Poids | 15 KG |

| Viscosité | <2000 cP |

| Capacité de mélange | 500-1000 litres |

Remarques

1. Installez un lubrificateur automatique de ligne d'air dans la ligne d'air à moins de 45 cm (0,5 mètre) ou aussi proche que possible du moteur à air. Le lubrificateur doit être installé en amont du moteur à air afin que la brume d'huile soit directement soufflée dans le moteur. Assurez-vous que le lubrificateur est toujours rempli d'huile.

2. Avant de connecter aux ports, nettoyez les raccords d'air comprimé avec de l'air à faible pression pour enlever toute saleté ou tout débris.

3. Utilisez toujours des lignes d'air qui sont de la même taille, ou plus grandes, que le port d'admission du moteur à air. (reportez-vous à la taille du port dans le tableau des spécifications).

EN

EN AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

ID

ID

TH

TH

TR

TR

MN

MN

NL

NL

LA

LA

EL

EL

RO

RO

SV

SV

TL

TL

HU

HU

AF

AF

MS

MS

AZ

AZ