- Introdução

Introdução

Os motores de ar da série HXCV são motores de engrenagem de ar de pás com caixas de engrenagem planetárias incorporadas na carcaça do motor. Eles podem também serem integrados com freios e embreagens pneumáticas no motor. Os motores pneumáticos de engrenagem HXCV têm um design extremamente compacto, então eles são muito menores e mais leves que os motores comuns de engrenagem pneumática. Eles estão disponíveis com diferentes razões de redução para atender a uma variedade de requisitos de velocidade e torque. São particularmente adequados para máquinas portáteis ou qualquer equipamento industrial que tenha limite no tamanho e peso do motor.

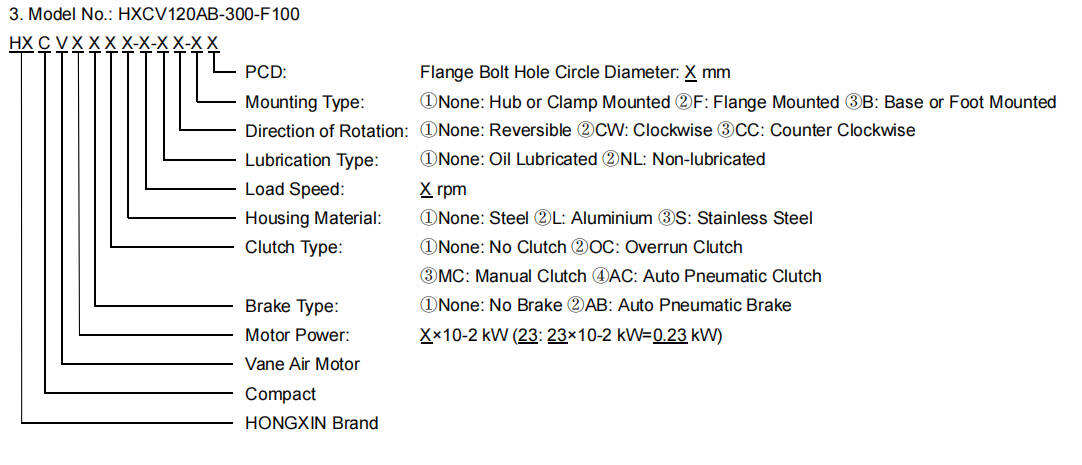

| Modelo do Motor | HXCV120AB-300-F100 |

| Potência do Motor | 1,20 kW |

| Velocidade sob Carga | 300 rpm |

| Torque | 40 N·m |

| Velocidade livre | 600 rpm |

| Sentido de rotação | Reversível |

| Pressão do ar | 0,69 MPa |

| Consumo de ar | 1500 L/min |

| Tamanho do porta | Entrada de Ar: NPT 3/8" Saída de Ar: NPT 3/8" |

| Diâmetro da mangueira | D.E.=14 mm | D.I.=10 mm |

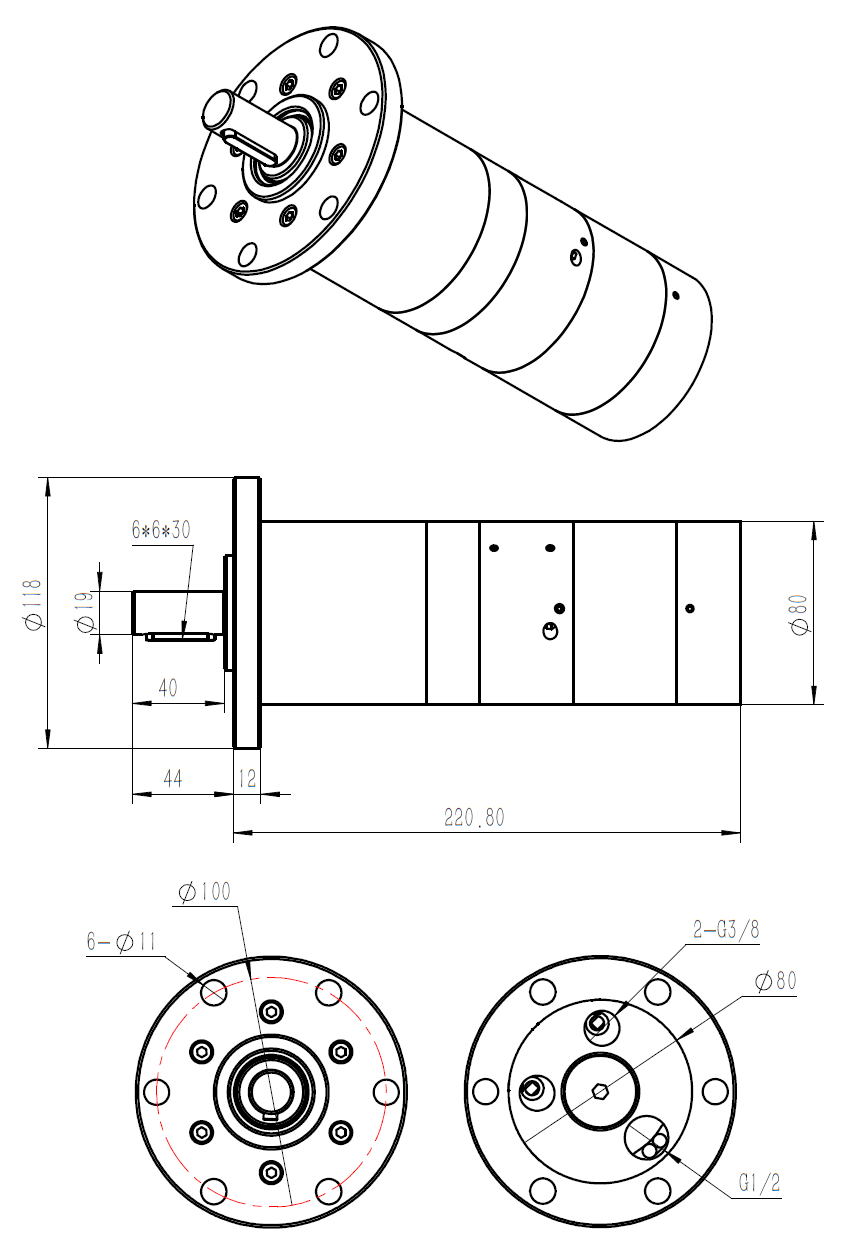

| Diâmetro do eixo | 19 mm |

| Material da Carcaça | Aço |

| Tipo de freio | FREIO A DISCO PNEUMÁTICO |

| Tipo de Montagem | Montado em Flange |

| Peso | 5 kg |

Observações

1. Instale um lubrificador automático de linha de ar na linha de ar a até 18 polegadas (0,5 metro) ou o mais próximo possível do motor pneumático. O lubrificador precisa ser instalado a montante do motor pneumático para que a névoa de óleo seja soprada diretamente para dentro do motor. Certifique-se de que o lubrificador esteja sempre cheio de óleo.

2. Antes de conectar às portas, limpe as conexões de ar comprimido com ar de baixa pressão para remover qualquer sujeira ou detrito.

3. Sempre use linhas de ar que sejam do mesmo tamanho ou maiores que a entrada do motor pneumático (consulte o tamanho da porta no gráfico de especificações).

EN

EN AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

ID

ID

TH

TH

TR

TR

MN

MN

NL

NL

LA

LA

EL

EL

RO

RO

SV

SV

TL

TL

HU

HU

AF

AF

MS

MS

AZ

AZ